A new year and a few more working days done at the bonded warehouses.

A very frosty work site first thing with a classic hot air balloon in the background.

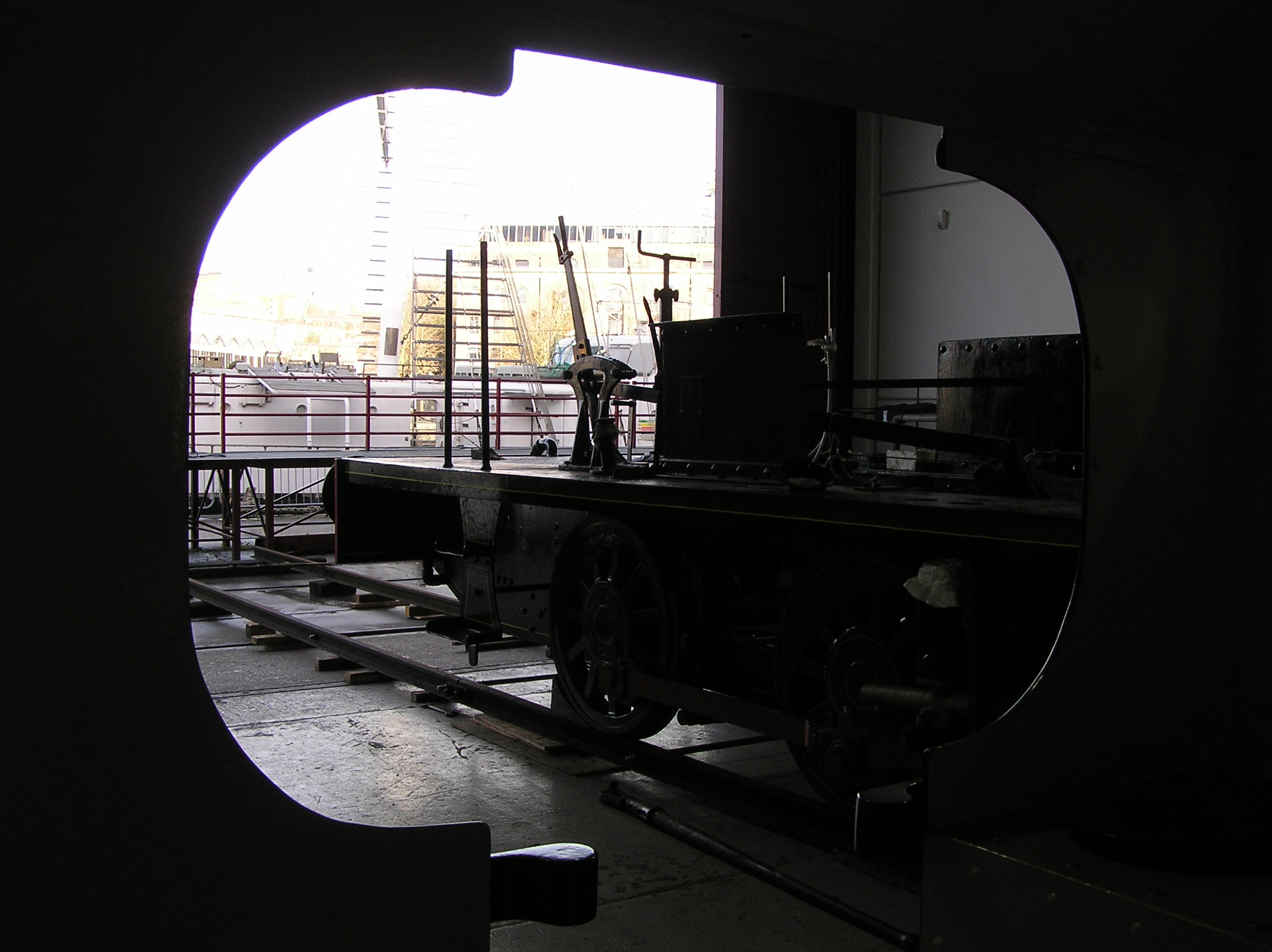

One of the first tasks was to begin curving the track panels towards the new station site. The running line has to allow for the yard to be put in on the South side as well as allowing access for machinery while we work.

Whilst we do have a winch, it was easier to use the loader buck to push the track around and start the curve. This was repeated at several points along the length of track (which was keyed but not fishplated together) to put a gradual curve in.

These views show the progress by early afternoon with another 2 rails being added and clipped/keyed, then more bending using the loader.

The view at the end of the first day shows the extent of new track, at this point about a third of the way to the station area. The sleepers in the foreground of the first photo were laid out before the curve was put in and show just how much of a bend has been added.

Another chilly start to Day 2, but with some beautiful frost and lighting as we added more rails. One of these fought us every step of the way, including having to be turned 180 degrees to put the unworn side facing inwards, then needing a lot of persuasion to sit in the chairs!

Alex is seen laying out the keys ready to be hammered in, then the current railhead is shown now that more track-bending has been done.

Thanks to Hayden and Chris for the additional photos.

Amelia and Chris were busy adding fishplates to the rails laid previously. As the track had now been bent, large gaps had opened up between the South side rails as the radius increased. This meant hammering out all the keys on a piece of rail, then jacking the rail horizontally to close the gap, re-keying and finally bolting fishplates in.

This process will need to be done along the whole of the new track here. These photos show the new fishplates as well as the impressive view of the line curving around and out of sight.

Whilst this was going on, the team also cracked on with taking apart the large stacks of wooden sleepers to avoid ‘painting ourselves into a corner’ – the running line will restrict access to the stores for the loader, so it’s better to lay out the sleepers we need alongside the trackbed, then later they can be dragged into place manually.

The sleepers are of variable condition. There will be some triage involved and the rotten ones will be cut up/salvaged for another use. The long-term plan will be to replace them all once the Coles Crane can access the site, but in the mean time we want to try and use the best of the wooden ones we have.

Similarly, the rail pile will need sorting through to get the best quality rails for the running line and lay them out alongside the trackbed ready to go in, but that’s a job for another day….